CIP #39 - Maturity Methods to Estimate Concrete Strength

WHAT is Concrete Maturity?

The maturity concept uses the principle that concrete strength (and other properties) is directly related to both age and its temperature history. Maturity methods provide a relatively simple approach for reliably estimating the in-place early-age compressive (and flexural) strength of concrete (14 days or less) during construction. The maturity concept assumes that samples of a concrete mixture of the same maturity will have similar strengths, regardless of the combination of time and temperature yielding the maturity. The measured maturity index of in-place concrete, a function of temperature history and age, is used to estimate its strength development based on a predetermined calibration of the time-temperature-strength relationship developed from laboratory tests for that mixture.

WHY use Maturity Methods?

Maturity methods are used as a more reliable indicator of the in-place strength of concrete during construction in lieu of testing field-cured cylinders. The traditional approach of measuring the strength of field-cured cylinders, cured in the same conditions as the structure, are used to schedule construction activities such as removal of forms or reshoring, backfilling walls, pre-stressing and post-tensioning operations, determining the time for opening the pavements or bridges to traffic, sawing joints, and to determining when protection measures can be terminated in cold weather.

Maturity methods use the fundamental concept that concrete properties develop with time as the cement hydrates and releases heat. The rate of strength development at early ages is related to the rate of hydration of cement. Heat generated from the hydration reaction will be recorded as a temperature rise in the concrete. The main advantage of the maturity method is that it uses the actual temperature profile of the concrete in the structure to estimate its in-place strength. The traditional approach of using field-cured cylinders does not replicate the same temperature profile of the in-place concrete and likely does not estimate its in-place strength as accurately. With maturity methods, strength information is provided in real time since maturity measurements are made on-site at any time. As a result, construction workflow is optimized, and construction activity timing can be based on more accurate in-place strength information.

HOW are Maturity Methods Used?

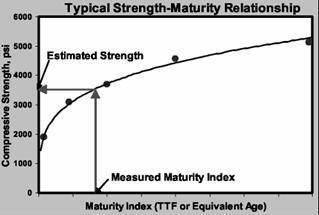

The procedure for estimating concrete strength using maturity concepts is described in ASTM C 1074, Standard Practice for Estimating Concrete Strength by the Maturity Method. The temperature-time-strength relationship of a concrete mixture is developed in laboratory tests. This establishes one of two maturity functions (explained below) for that mixture. During construction, a maturity index is determined from measured temperature and age. The maturity index is used to estimate the in-place strength from the pre-established maturity-strength relationship. This is illustrated in Figure 1.

Figure 1: Strength-maturity relationship from lab tests used to estimate in-place strength from measured maturity index. |

The maturity concept is governed by the underlying assumption that concrete samples of a given mixture will have the same strength when they have the same maturity index. For example, concrete cured at a temperature of 50°F (10°C) for 7 days may have the same maturity index as concrete cured at 80°F (27°C) for 3 days, and therefore would have similar strengths.

ASTM C 1074 provides two types of maturity functions: The Nurse-Saul function assumes that the rate of strength development is a linear function of temperature. The maturity index is expressed as a temperature-time factor (TTF) from the product of temperature and time in °C-hours or °C-days. The method requires a value for a datum temperature below which it is assumed that no cement hydration occurs. ASTM C 1074 provides a procedure to determine this value for the specific concrete mixture or suggests assuming a value of 0°C. The accuracy of the Nurse-Saul prediction breaks down when there are wide ranges of curing temperatures, but its accuracy is considered adequate for most applications.

The Arrhenius function assumes that the rate of strength development follows an exponential relationship with temperature. The maturity index is expressed in terms of an equivalent age at a reference temperature. Actual age is typically normalized to an equivalent age at 20°C or 23°C. A value of the activation energy is needed for this maturity function. ASTM C 1074 provides a procedure to determine the activation energy or alternatively suggests that a value of 40,000 to 45,000 J/mol is a reasonable assumption for concrete with a Type I cement. Using the established maturity function, the actual age and measured temperature is converted to an equivalent age to predict the concrete strength.

The Arrhenius function is considered to be more scientifically accurate. However, the Nurse-Saul function is more commonly used by the various state highway agencies in the United States mainly due to its simplicity.

► The maturity method involves the following steps:

1) Determine a strength-maturity relationship for the concrete mixture to be used in the structure using materials and mixture proportions proposed for the project. Monitor the temperature history of the test

specimens using temperature probes embedded in one or more of the cylinders. Measure the compressive strength of standard-cured test cylinders at various ages. These data are used to establish the

maturity function (Nurse-Saul or Arrhenius).

2) Measure the temperature history of the concrete in the structure by embedding sensors at locations in the structure that are critical in terms of exposure conditions and structural requirements.

3) Calculate the maturity index from the recorded temperature and age.

4) Estimate the in-place strength of the field concrete from the calculated maturity index and the predetermined strength-maturity relationship (Figure 1).

► Some of the limitations of maturity methods that can lead to erroneous estimation of in-place strength are:

® Concrete used in the structure is not representative of that used for the laboratory calibration tests, due to changes in materials, batching accuracy, air content, etc.

® High early-age temperatures will result in incorrect prediction of long-term strength.

® Concrete should be properly placed, consolidated and cured-- conditions should permit continued cement hydration.

® Use of datum temperature or activation energy values that are not representative of the concrete mixture.

® Points (a) and (b) above are inherent limitations of maturity methods. ASTM C 1074 suggests that supplementary tests be conducted prior to performing safety-critical operations such as formwork

removal or post-tensioning. While these additional tests are not always required, it is a good idea to periodically verify that the established maturity-strength relationship for the specific concrete is still

valid.

► Suggested methods include:

® In-place non-destructive tests ASTM C 803 (penetration resistance), ASTM C 873 (cast-in-place cylinders), or ASTM C 900 (pullout strength).

® Test method C 918 that projects later age strength from early age tests.

® Using accelerated curing of test specimens to estimate later age strength according to ASTM C 684.

® Early-age tests of field molded cylinders instrumented with maturity instruments.

® Strength-maturity relationships, datum temperature and activation energy are concrete-mixture specific. Therefore any significant modifications to the mixture design or material source should be

accompanied by a recalibration of these values.

Several maturity devices are commercially available that continuously measure concrete temperature, calculate maturity and display the maturity index digitally at any time. An unlimited number of locations can be monitored simultaneously. It is important to select a system that is rugged, provides uninterruptible and unalterable data, supports the maturity function being used for the project, and allows adjustment of the appropriate maturity constants.

It is important to realize that maturity is not intended to replace standard cured cylinder testing. Maturity used in conjunction with other non destructive testing can replace field cured cylinder testing and facilitate decision making for construction operations. It can be a good tool for quality control while reducing the amount of strength tests performed. Because of maturity testing, projects are proceeding more quickly, safely, and economically as a result of having the right information at the right place and at the right time.

References

1. ASTM C 1074-04, Standard Practice for Estimating Concrete Strength by the Maturity Method, ASTM International, www.astm.org

2. Guide to Non Destructive Testing of Concrete, FHWA, Publication No. FHWA-SA-97-105, Sep. 1997, www.fhwa.dot.gov/pavement/

3. Significance of Tests and Properties of Concrete and Concrete-Making Materials, ASTM STP 169C, ed. Klieger, P., and Lamond, J.F.,1994, www.astm.org

4. Carino, N.J., "The Maturity Method,” Chapter 5 in Handbook on Nondestructive Testing of Concrete, 2nd Edition, Malhotra, V.M., and Carino, N.J., Eds., CRC

Press Inc, Boca Raton, FL, and ASTM International, 2004.

2006

![]()